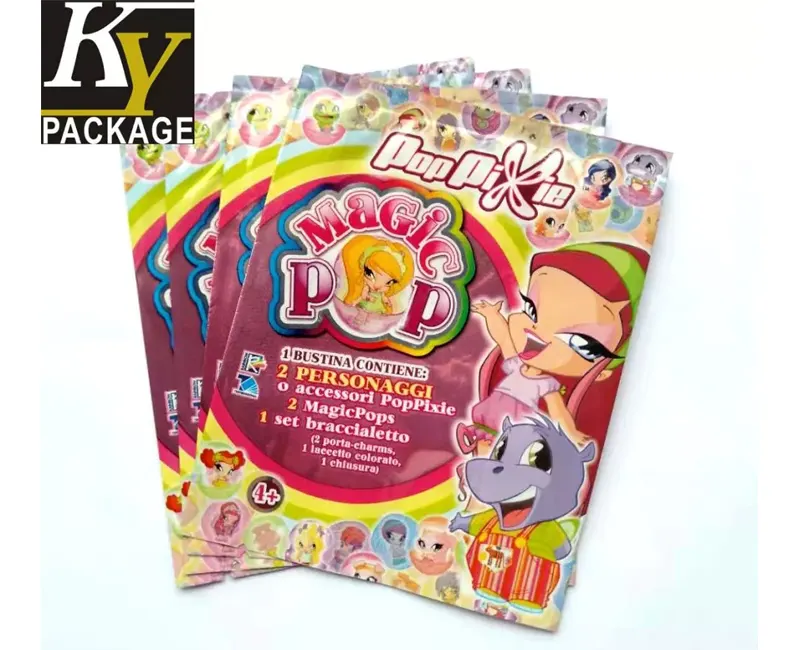

Aluminum Foil Plastic Packaging Bags For Toys

Send Inquiry

Medical and Medicine bag application:

The demand of a special soft bag packaging material is a roll bag, which provides the extreme durability of the order to perform the market. Opponents, gray or white, accept high -resolution graphics, text, and barcodes in embedded printing, eliminating the need for separate label operations.

The benefits of packaging bags: can be printed, completely opaque with good thermal strength and high durability plastic bag film.

Material parameter table:

AMBR-95 % of UV anti-ultraviolet rays, corrosion resistance, light transmission

AMBW-95 % anti-ultraviolet, transparent/white combination

BLK-Black opaque low-density polyethylene, safety and light protection

CLE-transparent low-density polyethylene

CVCI-anti-rust film

CWDC-DURACLEAR2000 transparent/white combination low-density polyethylene

CWT, CBLK, CLGY --- transparent, white, black and gray combination color of low density polyethylene

DC2-DURACLEAR2000 transparent low-density polyethylene

DC21-DURACLEAR2000SPECGRADE transparent low-density polyethylene

ECLE-biodegradation transparent polyethylene

EWHT, ECWT, EGCL-Bio-degradable white, transparent/white and green tone

EDC2-biodegradation increase type DUCLEAR2000

EWDC, ECWD, EGDC-biodegradation add-up Duraclear2000 white, transparent/white, green film

ICE1-Frozen Environment thin film

NSCR-scraper film

PLC1-POLYCLEAN transparent high-density polyethylene

WDC2-DURACLEAR2000 white opaque low-density polyethylene

Wht-white opaque low-density polyethylene

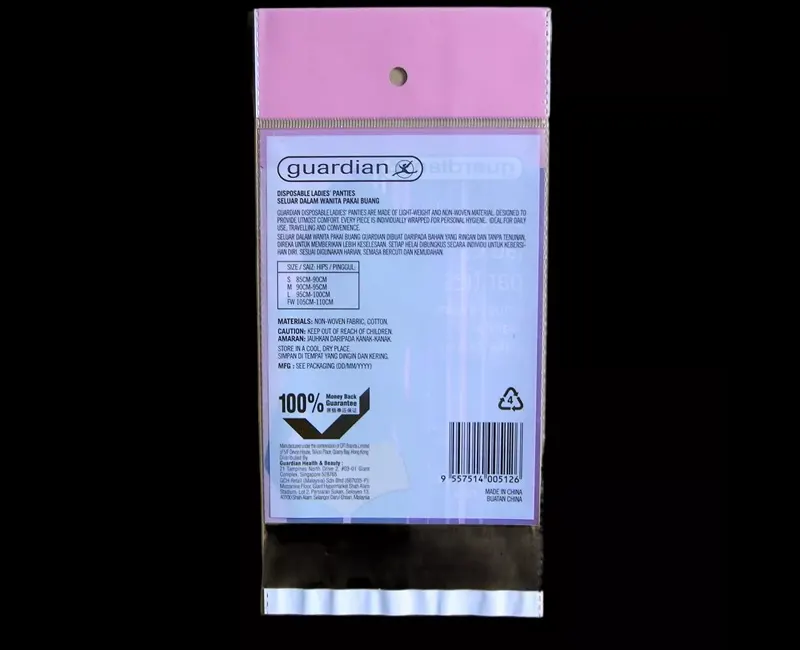

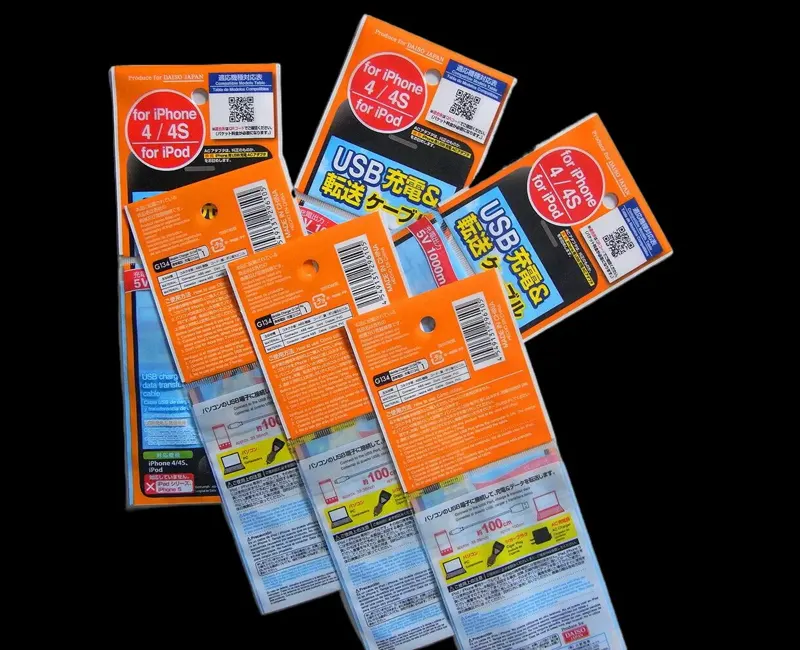

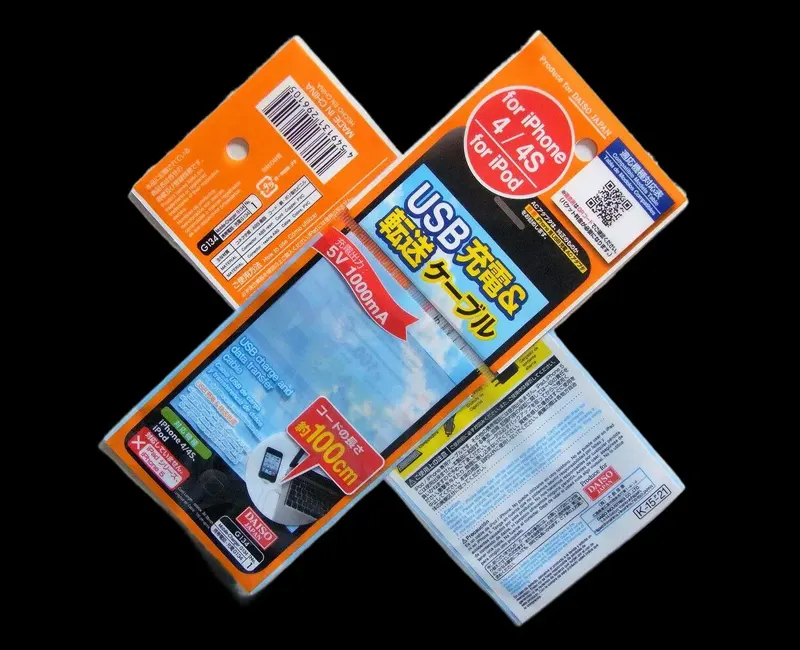

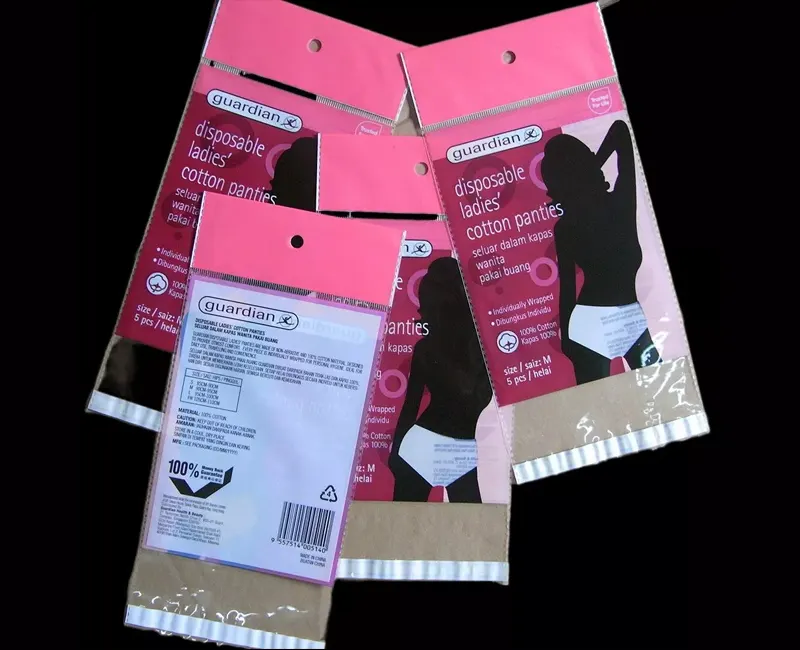

Product Details

Packing & Delivery

Applications

Our Certifications